Chickpeas, lentils, beans and peas are a fast-growing food market, with new uses going well beyond bean salads and hummus—think brownies, vegan meats, and salad dressing. Researchers like Chitra Sivakumar are working to drive dining innovation by studying the tiniest details of flours made from these pulses. Sivakumar has three publications in the journal Advanced Powder Technology.

“This is what I want to create, what the research is about: a specific flour for a specific product,” says Sivakumar, who conducted her doctoral research on pulse flours under the supervision of Dr. Jitendra Paliwal at the Grain Storage Research Lab at the University of Manitoba.

The study explored how particle size, protein and starch, and other micro-properties of milled pulse flour influence the quality of the end product. Processing rice and wheat flours is standardized because century-old research on these crops has helped establish and optimize particle size for milling; however, pulse flours have not received the same attention.

Sivakumar explains that consumers and food producers are interested in pulse-based food products because beans and lentils are great sources of fiber and protein. They’re also good for the environment: Pulse Canada estimates that growing 10 million acres of pulses can capture 4.1 million tons of CO2 emissions per year—the output of approximately 1.2 million passenger vehicles.

Wrj"/>

mZj"/>

4QM"/>

“Many consumers want to switch to the pulse-based proteins rather than animal-based proteins. But when they are looking in the grocery store they do not have many options,” says Sivakumar. She is using the Canadian Light Source (CLS) at the University of Saskatchewan to conduct specialized research aimed at changing that.

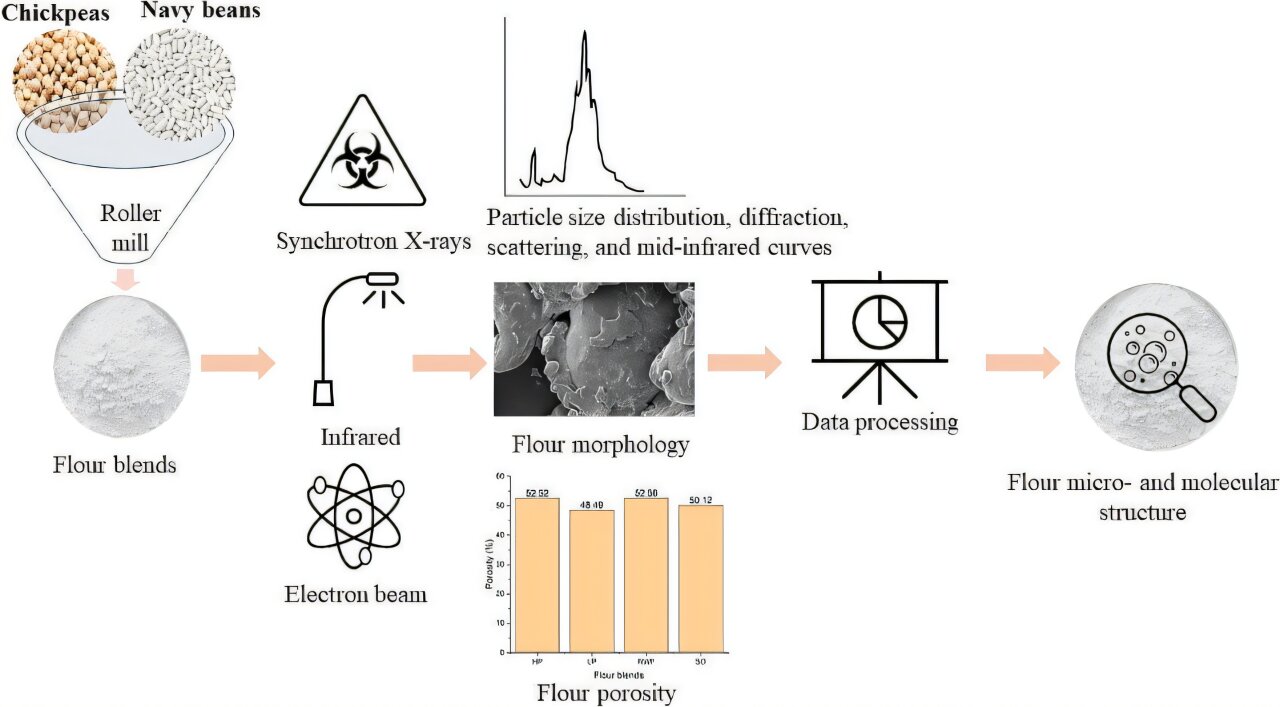

Sivakumar and her colleagues studied more than 60 flours from four pulse crops to understand how milling affects them. The ultrabright synchrotron light enabled them to see how starch and proteins were mixed together, the extent to which they were damaged by milling, as well as texture, getting a molecular-level picture of the size and distribution of the milled particles—not just at the surface, but within the flour.

“All these results can be applied on both the agricultural producer side and in pulse milling processes,” says Sivakumar. Her research into starch and protein can inform decisions on what varieties to plant for different purposes, while the insights into particle size can help refine milling techniques.

“I am so glad we were able to use this wonderful facility for our research. The resolution and accuracy level is so good—I would say it is really brilliant.”

More information:

Chitra Sivakumar et al, Investigating the microstructure of chickpea and navy bean flour blends produced by roller milling: Insights from Fourier transform mid-infrared spectroscopy, scanning electron microscopy and synchrotron X-ray techniques, Advanced Powder Technology (2024). DOI: 10.1016/j.apt.2024.104674

Chitra Sivakumar et al, Unravelling particle morphology and flour porosity of roller-milled green lentil flour using scanning electron microscopy and synchrotron X-ray micro-computed tomography, Powder Technology (2024). DOI: 10.1016/j.powtec.2024.119470

Chitra Sivakumar et al, A comprehensive assessment of microscopic characterization techniques to accurately determine the particle size distribution of roller-milled yellow pea flours, Powder Technology (2024). DOI: 10.1016/j.powtec.2024.119374

Provided by

Canadian Light Source

Citation:

Improving pulse flours for consumer use: Using synchrotron light to determine optimal particle size for milling (2024, November 8)

retrieved 8 November 2024

from Qes

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.